The Shower Kerfuffle: Learning Modeling By Printing A Shower Handle And Fixing A Worn Out Stem

Friday • December 31st 2021 • 6:30:55 pm

This strange poem is not really about fixing old plumbing,

it is about the power of design.

I don't particularly need a lion head tub handle,

but I am speechless about what a wonderful way to further my 3D modeling skills this is.

When there is nothing to do on holidays,

but wait for the stores to reopen, I take to creating cool things.

Originally I would write little programs,

but now I also compose, and as the case is today refuse to properly fix my shower.

With a horrendous roar,

my shower announced it needs new washers.

The repairs only take a short moment,

but it took a long time to understand what is going on.

In short the Tub Spout is destined at a wrong angle,

small drops of water will run along the tub spout and into the wall.

The water leaks because,

the washers get used up.

And the washers get used up,

because the pipe that washers press against has corded and became sharp.

The corroded assembly maybe 40 years old,

I may need to to use my dremmel to take off the edge.

I think of this as fun detective work,

I would never guess that the minor leaks can run along the tub spout into the wall.

Instead of just dripping down,

like it should - where is gravity when you need it.

And then of course the newly broken knob,

squeaked at me again as if to inquire on the status of her redesign.

The water stem that stick out of the wall,

has these little grippy teeth that have worn out as it is a soft metal.

This calls for a replacement which probably costs $10,

but not before I try to print out my own idea of how it should all work.

This looks like a job that will include the use of epoxy glue,

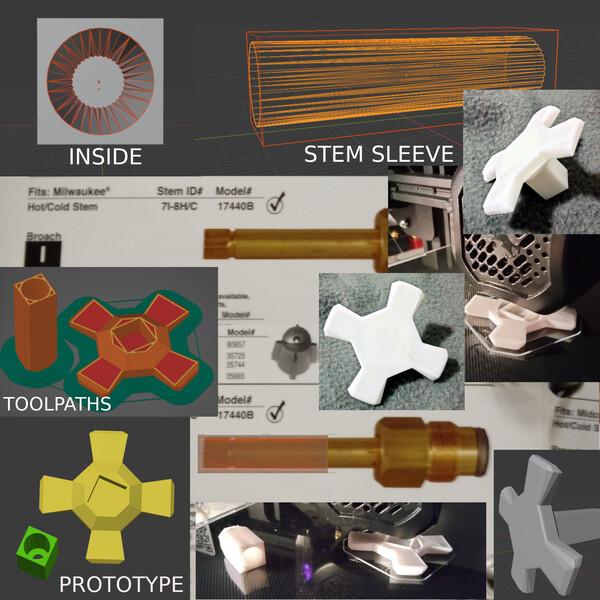

I've designed a stem sleeve with its own teeth that are meant to get in between the worn out ones.

With hopefully quick drying hard epoxy glue,

it shouldn't be a problem at all.

The reason I designed the stem sleeve separately from the shower/tub handles,

is because I want to try out different designs.

This is also why I made the water stem that sticks out of the wall and holds the handles,

square.

My design does not need a screw it just snaps on,

there is a square hole in the back of the handles I designed.

The square sleeve can accept simple designs,

but also things like lion heads, anything.

It is worth mentioning that there are overhangs in these parts,

one example is the inset screw at the end of the stem sleeve.

That means I need to use supports,

this is an automatic feature of slicing software.

It just fills in where the printer would be forced to print on air,

and the fill is like a simple mesh that is easy to snap off.

The supported surface will fee rough after removal of the support material,

that can mean sanding it down, or in my case leaving it be as the inset is covered by the screw head.

3D Modeling for 3D printing has to take air gaps under consideration,

this can be challenging in complex designs.

The machine-gun like wallet I recently made,

actually started off on paper, and completely eliminates the need for supports.

It is is my first large print out and it does suffer from warping,

though it is just the outside part of the wallet.

Warping is another thing to consider during 3D modeling,

to put it simply plastic shrinks a tiny bit as it dries.

Sometimes this may cause lifting of the part being printed,

which demands setting the print surface hotter and a brim.

Brims, like the brim on a hat,

aim to prevent a part from lifting.

All these issues, require practice,

and to make practice fun, fixing things around the house is the way to go.

Which is why I made my shower,

the subject of today's poem.

The lions head handle,

is actually the beginning of my New Year's resolution.

With what I have learned thus far,

I am able to add Designing Jewelry as a hobby.

I print in plastic because it is inexpensive and great for prototyping,

but there are companies that print in wax to make molds, and pour molten metals inside.

While it is too scary for me,

some people are fine with lost wax casting at home.

I think it is somewhat of a tradition to make a Lion's Head ring,

and that will be my first project of this New Years resolution: Begin Designing Jewelry.

It does not actually cost me anything up front,

the rings will only be poured after a purchase is made.

They won't be too expensive to the customer either,

I will sell in Bronze, Gold and Silver.

In closing, I want to present this little story,

as an example of self education.

There is not time in school to learn for real,

it may not be possible to get a solid education out of a standardized curriculum.

We are thinking beings,

we must learn, and we must learn for real.

Real skills,

that enable us to create real things.

We need context for learning,

be it a shower handle or a precious jewelry piece we need a reason to learn and remember.

We must not allow ourselves to be tricked into a fake education,

that only wastes our time.

Self Education above all,

and from Knowledge comes Wisdom, and from Wisdom Greatness.

Happy New Year.